Product Description

Versogen Dispersions

Versogen’s PiperION® dispersion (5 wt%) is one of the critical components of achieving superb performance with PiperION® membranes. Dispersions are usually used to prepare the anode and cathode catalyst inks or slurries. Presence of a dispersion within the catalyst layer will significantly enhance the ionic conduction phenomenon in the catalyst layer, and hence, better electrochemical performances. Dispersions can also be used to manufacture the self-supporting membranes and mechanically reinforced membranes too. PiperION® dispersion belongs to the anion exchange category of dispersion products and should be used for applications where the transfer of anions are critical for the electrochemical performance.

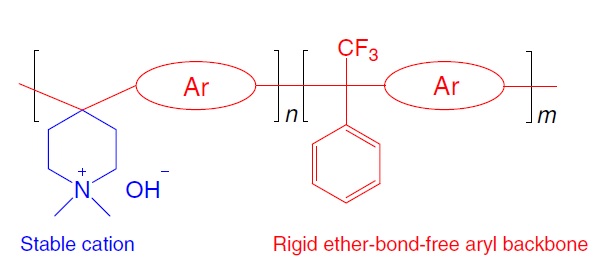

PiperION® dispersion (5 wt%) is manufactured from the functionalized poly(aryl piperidinium) polymer. The general chemical structure of the poly(aryl piperidinium) resin material is provided below.

-Excellent chemical durability and stability in the pH range of 1-14 due to rigid ether-bond-free aryl backbone

-Long lifetime operational capability in a wide temperature range

-Manufacturing of anode and cathode catalyst layers with super ionic conductivity

-Manufacturing of self-supporting or mechanically reinforced membranes

PiperION® dispersion (or any other dispersion) would usually be used in the as-received form and the products generated from the dispersion material would then be converted into the desired ionic form.

Any product (such as catalyzed gas diffusion layers, gas diffusion electrodes, MEAs, CCMs) that contains the PiperION® dispersion should follow the protocol below if it is going to be used for standard alkaline fuel cell / electrolysis applications in order to convert the ionically conductive PiperION from bicarbonate form to the hydroxide form.

If the manufactured product from PiperION® dispersion is a membrane, then allow the membrane to sit at ambient conditions for 1 hr without a cover sheet prior to its submersion. If the product is a CCM (without GDLs), then allow the CCM to sit at ambient conditions for 1 hr without any cover films or backing films prior to its submersion. If the product is an MEA (meaning GDLs are permanently bonded to the membrane), the conversion of the ionically conductive parts needs to be carried inside a setup where the MEA is being restrained or under mechanical clamping force and it is not advised to remove the MEA after the conversion in order to prevent delamination of the GDLs from the membrane surface. If the manufactured product from PiperION dispersion is a catalyzed GDL or GDE, then the submersion step can be done immediately.

For hydroxide exchange membrane fuel cell or hydroxide exchange electrolysis applications or any other application that requires the hydroxide ion transfer, the product should be converted from bicarbonate form into OH- form for optimal conductivity.

To convert the manufactured product to OH- form, place the product in an aqueous solution of 0.5 M NaOH or KOH for 1 h at room temperature. After 1 h, replace the solution with fresh 0.5 M NaOH or KOH and allow the membrane to soak for 1 h at room temperature again. After the two soaks, rinse the product with DI water (pH ~ 7). Minimize exposure to ambient air, as the CO2 can exchange back into the membrane causing the membrane to convert back to bicarbonate form. The reaction between CO2 and hydroxide ions is purely chemical and it will readily happen if the OH- form of the manufactured product is exposed to an environment that has CO2 (such as ambient air, etc.). This conversion can be completely eliminated by simply doing the conversion and testing in a CO2-free drybox environment.

Any product (such as catalyzed gas diffusion layers, gas diffusion electrodes, MEAs, CCMs) that contains the PiperION® dispersion should follow the protocol below if it is going to be used for electrochemical reduction of CO2 or CO2 electrolysis applications in order to convert the ionically conductive PiperION® from bicarbonate form to another anionic form.

If the manufactured product from PiperION® dispersion is a membrane, then allow the membrane to sit at ambient conditions for 1 hr without a cover sheet prior to its submersion. If the product is a CCM (without GDLs), then allow the CCM to sit at ambient conditions for 1 hr without any cover films or backing films prior to its submersion. If the product is an MEA (meaning GDLs are permanently bonded to the membrane), the conversion of the ionically conductive parts needs to be carried inside a setup where the MEA is being restrained or under mechanical clamping force and it is not advised to remove the MEA after the conversion in order to prevent delamination of the GDLs from the membrane surface. If the manufactured product from PiperION® dispersion is a catalyzed GDL or GDE, then the submersion step can be done immediately.

The PiperION® dispersion is shipped in the bicarbonate form. If you are working with bicarbonate electrolytes in your setup, then there is no need to pretreat the product manufactured from PiperION® dispersion and it can be used in the as received form.

If you are working with carbonate electrolytes, then the product manufactured from PiperION® dispersion needs to be converted to carbonate form. In order to achieve this, simply submerge the product in an aqueous solution of 0.1 – 0.5 M sodium carbonate or potassium carbonate for 12 h at room temperature. After then, replace the solution with fresh 0.1 – 0.5 M sodium carbonate or potassium carbonate and allow the manufactured product to soak for 12 h at room temperature again. After the two-three soaks, rinse the manufactured product with DI water (pH ~ 7).

Instead of bicarbonate or carbonate electrolytes, if you are using KOH or NaOH type pure alkaline electrolytes in your CO2 reduction experiments, then you can simply follow the “For standard alkaline fuel cell / electrolysis applications” protocol for converting the manufactured product to OH- form.

Any product (such as catalyzed gas diffusion layers, gas diffusion electrodes, MEAs, CCMs) that contains the PiperION® dispersion should follow the protocol below if it is going to be used for other electrochemical applications in order to convert the ionically conductive PiperION® from bicarbonate form to another desired anionic form.

If the manufactured product from PiperION® dispersion is a membrane, then allow the membrane to sit at ambient conditions for 1 hr without a cover sheet prior to its submersion. If the product is a CCM (without GDLs), then allow the CCM to sit at ambient conditions for 1 hr without any cover films or backing films prior to its submersion. If the product is an MEA (meaning GDLs are permanently bonded to the membrane), the conversion of the ionically conductive parts needs to be carried inside a setup where the MEA is being restrained or under mechanical clamping force and it is not advised to remove the MEA after the conversion in order to prevent delamination of the GDLs from the membrane surface. If the manufactured product from PiperION® dispersion is a catalyzed GDL or GDE, then the submersion step can be done immediately.

Prior to the assembly of the manufactured product from PiperION® dispersion into the electrochemical device or setup, the product should be converted into the anionic form that is relevant for the intended application. For example, if the application is requiring the Cl- anions to be transferred through the manufactured product, then it needs to be converted into the Cl- form. In order to convert it into Cl- form, it needs to be submerged into a 0.1 to 0.5 M salt solution of NaCl or KCl (dissolved in deionized water) for a period of 12-24 hours and then rinsed with deionized water to remove the excess salt from the product surface. Or if the intended application is requiring to transfer sulfate anions across the manufactured product, then it needs to be converted into the sulfate form prior to its assembly into the cell. A neutral salt solution of 0.1 to 0.5M Na2SO4 or K2SO4 would usually be sufficient to achieve the full conversion of it into the sulfate form after fully submerging the product into the salt solution for 12-24 hours at room temperature. It is always suggested to repeat the submersion process for 2-3 times in order to achieve close to 100% conversion and then rinse it with copious amount of deionized water.

Reviews

There are no reviews yet.